Collaborators

Tags

SEMI StandardsWater ConservationFiltrationSustainable water treatment technology: trends and challenges

As fabs increasingly look to meet environmental sustainability goals, what are the barriers to water reuse, and what technologies are available to help address these challenges?

Share this insight

To engage in conversation about this topic with tool and technology experts from across the microelectronics supply chain, register for the next UPM Community Event: Environmental Sustainability Roundtables on February 24. Do you have your own perspective on this topic? If so, please post a Industry Insight post to share your knowledge with the UPM community.

Accelerating demand for semiconductors and technological breakthroughs in manufacturing are driving up water consumption across the microelectronics industry, creating opportunities for water management practices and treatment technologies which improve the environmental sustainability of operations. Manufacturing advances such as the uptake of extreme ultraviolet lithography (EUVL) and the transition to FinFet are further driving up ultrapure water (UPW) use. Adding to the problem are plans to build many new fabs in water-stressed regions, such as Taiwan and the southwestern US.

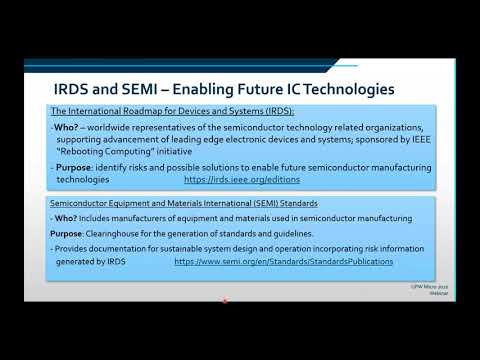

Faced with the need to balance growth with water conservation, the industry is increasingly turning its attention to innovative water management strategies. This trend led industry association SEMI to publish two important new standards in 2020 – SEMI F98 and SEMI Guide 6600 – both of which offer guidance on topics integral to reuse, such as wastewater stream segregation, the benefits of centralized and decentralized treatment systems, water-saving applications in tools and key performance indicators.

While water recycling is gaining momentum, several related challenges inhibit large-scale adoption of the practice. These include the complexity of plant effluent, the high energy requirements of plant water systems, brine management difficulties, the need to maintain microbiological control, and the impacts of reuse approaches on capital and operating budgets. Fortunately, technology providers are offering solutions which help manufacturers push ahead with recycling.

Simplifying wastewater management through stream segregation Since UPW rinse water is relatively contamination free, there is significant opportunity for the semiconductor industry to reduce its water footprint by either returning flows to the UPW generation plant or reusing them in wet scrubbers and cooling towers. Implementing different tool drains for UPW drain segregation can minimize extra treatment steps, as different qualities of UPW can be returned to different stages of the UPW generation plant. In addition, conductivity sensors in segregated tool drains quickly detect contaminated UPW rinse water and allow operators to respond accordingly. By segregating wastewater streams as close as possible to the point of use, manufacturers can avoid additional treatment steps, thereby reducing chemical and energy use, and subsequently, operating costs. This practice can also simplify processes such as brine management and resource recovery. Segregating easily treatable, low-TDS streams (such as wastewater generated in silicon wafer backgrinding and dicing processes) from high-TDS streams (such as chemical-mechanical planarization wastewater) can also make reuse more viable. Not only can stream segregation mitigate scaling-related maintenance, but it also creates an opportunity for low-TDS volumes to be treated solely with membrane technologies and used as deionization plant feedwater. Minimizing brine by optimizing chemical use Chemical use in treatment processes contributes to the salinity of plant effluent, something which is already rising due to greater use of acids in etching processes during the manufacture of advanced nodes. Where salinity levels exceed discharge requirements, fabs must employ additional treatment to ensure compliance. However, doing so yields brine, another waste whose disposal is complex and costly. Several membrane technologies are available to treat wastewater without the need for additional chemicals. For example, Pall offers a method for treating hydrofluoric acid wastewater via crossflow hollow-fiber membranes instead of the traditional neutralization process, which requires chemicals such as calcium chloride, lime, hydrochloric acid and sodium hydroxide, as well as polymers for flocculation. With Pall’s process, only a fraction of the wastewater feed must be treated with chemicals. Such filtration systems can also be maintained with minimal chemical cleaning, further adding to the benefits. Reducing UPW volumes without compromising microbiological control To avoid wafer defects resulting from microbiological contamination idle flows must be run across wet processing tools when they are not running wafers. Doing this may require greater UPW volumes than are consumed during active wafer processing. Because low flow rates can also lead to contamination, there is opportunity for the implementation of digital technologies to determine when an adequate rinse is achieved, and thereby minimize UPW usage. Balancing energy and water needs Energy consumption can be improved across most water treatment systems. UPW generation is energy-intensive, since heating, cooling and ultraviolet treatment are required to meet quality parameters. As such, efforts towards reducing, reusing or recycling UPW also contribute to energy savings. Data-driven energy optimization for tools using UPW is gaining traction, with predictive control technologies improving the energy consumption of pumps and other components when UPW flows change or tools resume operations after downtime.

Energy efficiency is a growing challenge for wastewater treatment systems as well. DAS Environmental Expert (DAS EE) engineers see potential for applying data-driven methods to make its treatment systems more energy efficient. Optimization can be done by integrating appropriate sensors and measurement tools for monitoring and employing online data collection software and simulation programs.

Raising the cost competitiveness of sustainable approaches Operational savings stemming from reduced water, chemical and energy consumption may encourage manufacturers to optimize the sustainability of their water management practices. Technology providers are aware that longer-term cost optimization alone may not be enough to sway manufacturers to adopt water recycling programs. Some firms, such as DAS EE, are developing additional approaches for quicker returns on water system investments.

DAS EE sees an opportunity for resource recovery with physical-chemical methods. The company is particularly interested in the potential to recover rare metals such as germanium, gallium and indium, from the industry’s wastewater, something that would require stream segregation. These metals could then be sold in raw form, or even recycled into products such as fiber-optic cables, optoelectronics and display technologies.

Share this insight

Related resources

Solutions to the IPA Abatement Challenge

Smart primary wastewater managament - Strategies, rules, examples

Semiconductor Industry Needs in UPW and Water Management During Turbulent Times