Collaborators

Tags

WastewaterWaste ManagementWhat is Veolia bringing to UPM 2023? The Azoles Treatment Challenge

Why is this a challenging emerging contaminant?

Share this insight

Rudy Labban, Technical Leader at Veolia Water Technologies, spoke to UPM about the emerging understanding of azoles in wastewater streams and methods to remediate their effects.

Azoles are widely used compounds critical to the semiconductor manufacturing process, but they present a steep challenge in wastewater treatment for multiple facility operators. Cost-effective and environmentally sustainable methods of remediating this class of contaminants are high on the industry agenda. Azoles play a critical role in the chemical-mechanical planarization (CMP) process. In manufacturing, operators use abrasive colloidal silica and corrosive acids to smooth the copper and insulator layers on the wafer. Azoles are corrosion inhibitors in this planarization process and protect the copper surface from excessive dissolution by corrosive acid.

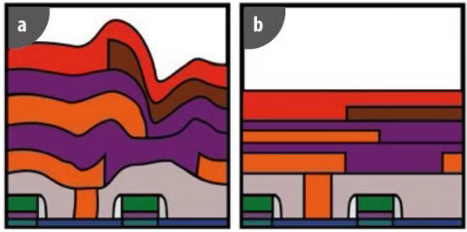

Figure A represents the wafer layers before the CMP step. Azoles are critical to getting from A to B by protecting the wafer from over-dissolution.

However, semiconductor facilities cannot send waste streams containing high concentrations of azoles to publicly owned treatment works (POTW), since azoles inhibit the biological conversion of ammonia to nitrates and water, causing difficulty in meeting ammonia limits. Rudy Labban, Technical Leader at Veolia Water Technologies and Solutions explained to UPM that understanding the effect of azoles on downstream processes is relatively recent, and it is an emerging area of research: ‘It used to be the case that semiconductor facilities sent azole-containing wastewater to the POTW to be mixed with wastewater from multiple industries. After employing the traditional method of biological treatment, the cities began to observe inhibition.’

Existing treatment techniques for azoles rely on advanced oxidation processes – either through ozone or Fenton reactions. However, both methods have drawbacks which the industry is working to solve.

Why are azoles so difficult to treat? Several factors contribute to the challenge, including:

- Organic content: It is less effective to use ozone-based oxidation in waste streams which contain high concentrations of organic matter, as this technique does not only target azoles, but indiscriminately targets all organics. As such, these specific waste streams require large volumes of ozone to treat azoles, which in turn increases treatment costs substantially.

- Byproduct formation: The oxidation of azoles can produce undesirable byproducts such as nitrates – which can contribute to additional environmental or regulatory issues or complicate the treatment process.

- Extra steps: Colloidal silica and other suspended solids must be removed first as an independent step before using ozone to oxidize the azoles.

- Disposal costs: Oxidation based on Fenton reaction produces sludge which is costly to manage.

In 2021, Veolia renewed its Azoles R&D Program to address these challenges and consequently at UPM 2023, they will present data for a novel approach and aspects which are subject to continued research. The new approach involves reacting the azoles with a compound that transforms the azole into a suspended solid to be removed through filtration or sedimentation. In the new process, colloidal silica and azoles can be removed during the same step through sedimentation.

That resultant sludge contains the azoles and the added chemical, and the latter can potentially be reused once separated from the azole. Veolia is actively seeking avenues to recycle or reuse the azoles, acknowledging that, while stringent purity requirements may limit their reuse in semiconductor manufacturing, they might find new life in other industries or applications. This is an ongoing area of exploration and research.

Share this insight

Related insights

Q&A Results with GlobalFoundries: Chemical Inhibition to Biological Wastewater Treatment

Zeph Egnasher

GlobalFoundries

From the archive: Taimur Burki on Chemical Reclamation and Reuse

Orla McCoy

Global Water Intelligence

Emerging trends for UPW and wastewater treatment

Orla McCoy

Global Water Intelligence