Achieving IPA removal in UPW from marangoni dryers in semiconductor production

Date Published: 2016 | Technical journal archive

Log in or Join UltraFacility to access this content

To access our resources you will need to be a member of UltraFacility, log in to your account or purchase a membership to view this content.

Already have an account? Log in

Drying of rinse water from parts is, for many process engineers, a final critical step of a process. Drying steps can be costly, energy and time consuming, and if not done properly will leave a non-volatile residue of minerals, detergents, and ions on the surface of the part - not to mention water stains. There are various methods of drying that may be employed; however, one of the best approaches is Marangoni drying for flat surfaces such as semiconductor wafers or disk drives.

Companies: Exergy Systems

Tags: UltraPure WaterTotal Organic Carbon (TOC)Isopropyl Alcohol (IPA)Ultraviolet (UV)

Related content

Training series | 2018

End-of-Pipe Semiconductor Wastewater Reclaim

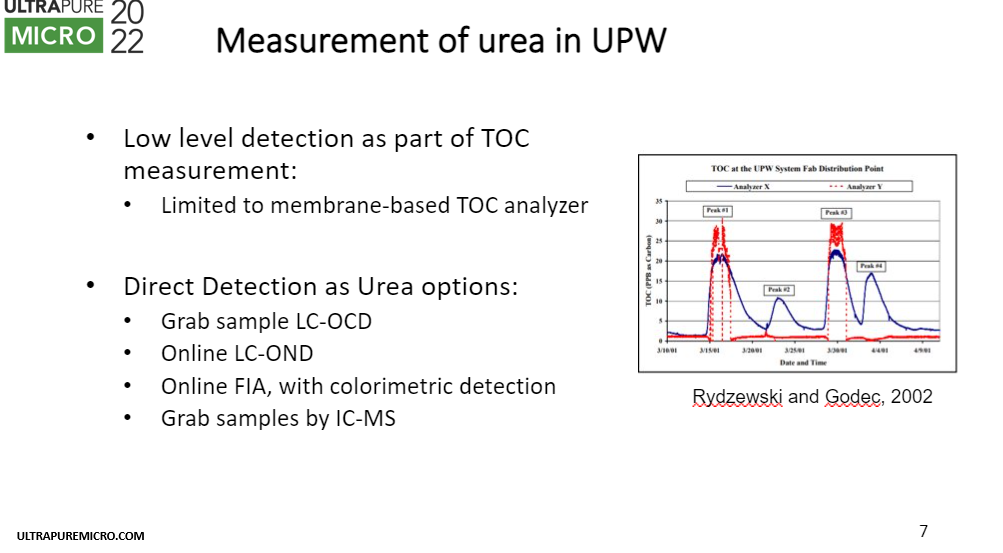

Conference material | 2022

What is Known About Urea Control in UPW Systems?

Conference material | 2018

U-PURTM – A Metal-Free Combination of Several UPW Polishing Steps in a Multifunctional Reactor for the Removal of TOC and H2O2 Traces

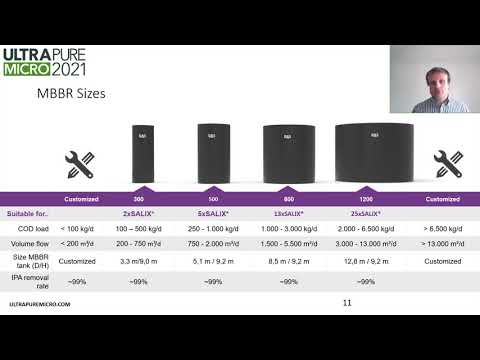

Conference material | 2021

Solutions to the IPA Abatement Challenge

Back to Technical Knowledge Base