Proactive particle control: Where is the research heading?

Share this insight

What difficulties is the semiconductor industry facing in proactive particle control?

As the killer particle size declines in alignment with decreasing node sizes and new chip structures, the limits of existing ultrapure water (UPW) metrology remain stagnant. As semiconductor facilities struggle to obtain high chip yield at manufacturing nodes below 7nm, research projects strive to understand the correlation between UPW and on-wafer defectivity.

It can be extremely difficult to understand the root cause of contamination throughout large, complex fabs. Malek Salamor, Senior Vice President of the Microelectronics Division at Ovivo, explained to UPM: ‘High yield for advanced semiconductor technology, such as technology manufactured at 2nm or 4nm nodes, is difficult to obtain. It is not always possible to determine if the contamination originated from chemicals, gases, the cleanroom, or somewhere else. However, water does could potentially cause a big impact to yield, as it is used everywhere throughout the fab'. Salamor explained the that the industry is investing in determining the correlation between UPW quality and wafer defectivity so that engineers can trace the source of contamination, understand the impact of different high-purity materials, and proactively address the reasons for quality deviations.

Ali Altun, CEO at UNISERS explained to UPM last year that characterizing the risk of on-wafer defectivity caused by liquids, requires better metrological methods. Detecting contamination spikes in liquids – and, most importantly, the extent to which quality deviations will actually cause defects on the wafer – is important for avoiding costly downtime. The company’s Surface Enhanced Raman Spectroscopy (SERS) technology can detect extremely small particles on-wafer, and has recently obtained $14 million in funding. The technology has also been used in key International Roadmap for Systems and Devices (IRDS) studies on proactive particle controls.

Where is the critical research heading?

As outlined in the IRDS 2021 white paper, controlled deposition experiments are important to make progress in understanding proactive particle control. Since the publication of the paper, what have been the research areas? Below are some of the issues that the IRDS and other collaborative partnerships are trying to tackle by understanding the relationship between UPW and wafer defectivity.

Organic contamination extracted from piping: Industry collaboration has driven the beginning phases of understanding the extent to which polyvinylidene fluoride (PVDF) and perfluoroalkoxy (PFA) piping may contribute to on-wafer defectivity. This study presented by Gary Schooneveld, Principal at CT Associates in collaboration with UNISERS demonstrates that hot UPW will extract particles and particle precursors extracted from PVDF and PFA piping and these particles will deposit differently on the wafer surface. Further research is required to understand to characterize the defectivity risk for different particle concentrations in the UPW.

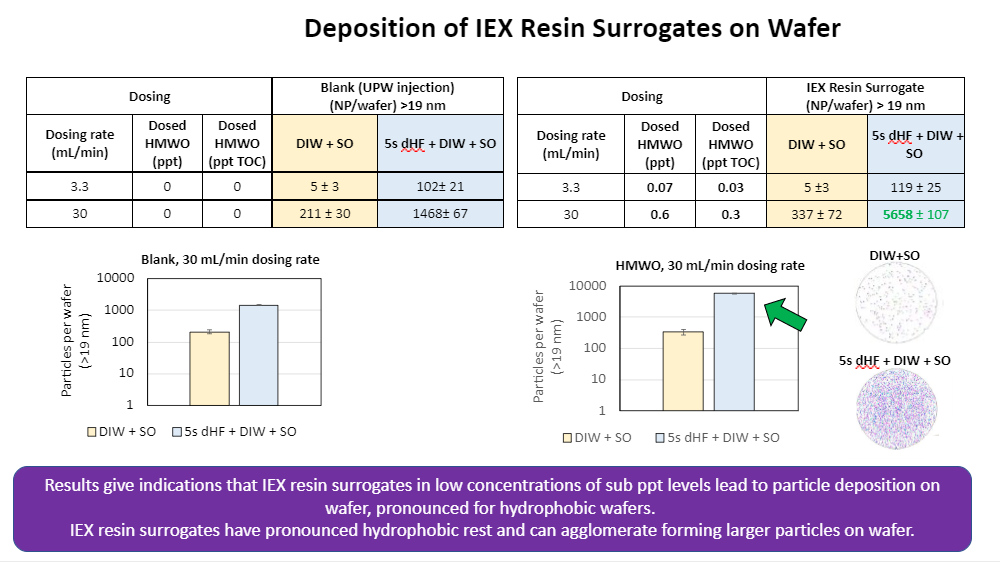

Ion exchange resin: Recent IRDS work has indicated that ion exchange resin, which is used in the final polishing stage, releases material into liquids and contributes to organic contamination on wafers. This presentation by Derek Oberreit, Senior Vice President at Kanomax FMT, shows the status of research into the impact of material released by ion exchange resin on wafer surfaces. Future research on this topic will involve SERS technology to compare more closely to other IRDS work on proactive particle control. In addition, the study will involve filters with different retention rates and different wafer surface types in the future, such as hydrophobic and hydrophilic wafers. The 2022 IRDS and SEMI update given at the UPM conference also contains details of the IRDS testing of the particle reduction capabilities of ion exchange resin at 6 UPW Systems, each from one of Intel, GlobalFoundries, and Micron.

Silica and iron oxide particles: Carried out at a full-scale UPW plant at the Lam Research test center, this collaborative study between Lam Research and Ovivo demonstrates the effect of silica and iron oxide particles on 300mm wafers. Key takeaways show that the difference in particle deposition varies significantly between hydrophobic and hydrophilic wafers and is generally higher for iron oxide than silica. This particular study found very low concentrations of particle deposition contributed by ion exchange resin.

Share this insight