Collaborators

Tags

PFASSustainabilityWhat is Kennedy Jenks bringing to UPM 2023? A new pilot in the PFAS destruction landscape

A discussion of the pros and cons of various PFAS destruction technologies, with Charlie Liu, National PFAS Lead at Kennedy Jenks Consultants

Share this insight

With incoming stringent regulations in the EU and the US aimed at cracking down on the discharge of per-and poly-fluoroalkyl substances (PFAS), the semiconductor industry finds itself exploring the realm of PFAS destruction technologies.

Although several market players are commercializing PFAS destruction technologies, at UPM 2023, Kennedy Jenks will present information on a pilot for one of the lesser-explored methods – UV-sulfite degradation – with transparent data on the benefits and drawbacks of this technology as it sits in the landscape of PFAS destruction technologies.

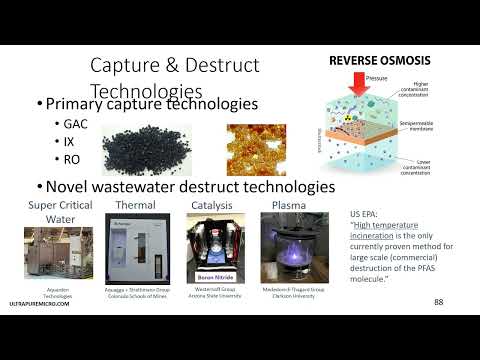

The most established technologies on the market for PFAS destruction are electrochemical oxidation (EO), supercritical water oxidation (SCWO), and hydrothermal alkaline treatment (HALT). Each method has its benefits and drawbacks. For example, SCWO requires high temperatures and pressures.

Although HALT and EO can operate at slightly lower temperatures and pressures than SCWO, Charlie Liu, National PFAS Lead at Kennedy Jenks Consultants told UPM ‘All these examples are generally energy intensive. PFAS are termed ‘forever chemicals’ for a reason – they are extremely difficult to degrade.’ Existing methods can also be energy intensive and require a high pH for operation. SCWO does present the benefit of not requiring chemical consumption, unlike its competitor HALT, which requires substantial quantities of hydroxide.

One drawback that all these technologies have in common is the necessity of specialist equipment. Kennedy Jenks undertook a pilot to demonstrate the potential of a method which could be an outlier to this rule. By concentrating waste streams with either reverse osmosis (RO) or nanofiltration (NF) followed by UV-sulfite destruction, the pilot only used components which are widely commercially available, such as UV lamps and reactors. Sulfite is also a relatively easily accessible chemical on the market. In times of prevailing supply chain bottlenecks and limited resource availability, these methods could prove useful for mitigating PFAS-containing waste streams.

The concept of concentration before destruction is one that market players are generally adopting to obtain more cost-effective destruction, as well as less temperature and pressure intensity. In the case of the UV-sulfite methods, operators can also use reactors with a smaller footprint when treating more concentrated streams. The data for this pilot will show comparative evidence for both the NF and RO stage before the destruction step. Results showed that although NF offered a lower energy consumption, it rejects long-chain PFAS better than short-chain PFAS.

At UPM 2023, Kennedy Jenks will report a comparison on the use of both NF and RO in this pilot, as well as transparent data on the energy and chemical consumption of the overall method. One key conclusion was that the treatment process is not currently continuous, as it takes several hours to perform the complete destruction (which is considerably longer than some of the other emerging PFAS destruction technologies). However, it is possible to consider solutions to render the process more continuous, which might involve adding a membrane process or adsorbent after the RO stage. Possibilities for this concentration step include foam fractionation or ion exchange (though, for the latter, it is necessary to consider how to dispose of the associated PFAS-laden waste). As such, the method is subject to continued research and exploration.

Share this insight

Related insights

Greenhouse gas emissions efforts turn their attention to the supply chain - End-user sustainability trends revealed

Georgia Bottomley

Global Water Intelligence

How do we actually drive transformative change in semiconductor facilities? UltraFacility 2024 Closing Panel Report-Out.

Orla McCoy

Global Water Intelligence

News-in-Brief: January 2024

Related resources

Not-So-Forever Chemicals: Field Demonstration of PFAS Destruction by a Pilot-Scale Nanofiltration and UV-Sulfite Treatment Train

PFAS - The Next Great Wastewater Challenge