Can a New Polyamide Chemistry Improve RO Rejection of Boron, Nitrates and Silica

Date Published: 2016 | Technical journal archive

Log in or Join UltraFacility to access this content

To access our resources you will need to be a member of UltraFacility, log in to your account or purchase a membership to view this content.

Already have an account? Log in

The commercialization of a high cross-linked polyamide (PA) separation layer for Reverse Osmosis (RO) membrane application has displayed potential in laboratory development work to deliver improved rejection performance for 'bulky' anions, frequently problematic in Reverse Osmosis (RO) (RO). This refined performance reduces the cost of system operation as well as reducing regeneration costs. This article expands on RO membrane chemistry and presents data illustrating differences before and after RO membrane replacement.

Related content

Conference material | 2024

PFAS Treatment with Ion Exchange Resins for Semiconductor Industry

Conference material | 2021

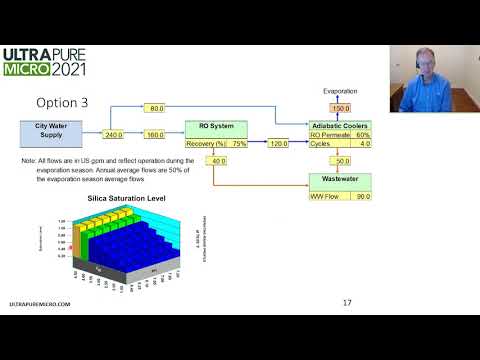

Doing more with less - minimizing data center water and wastewater

Technical journal archive | 2010

Use of Unique Fractional Electrodeionization in Power Plant Applications

Conference material | 2022

Advanced precipitation membrane treatment systems for fluoride wastewaters and RO scaling brine

Back to Technical Knowledge Base